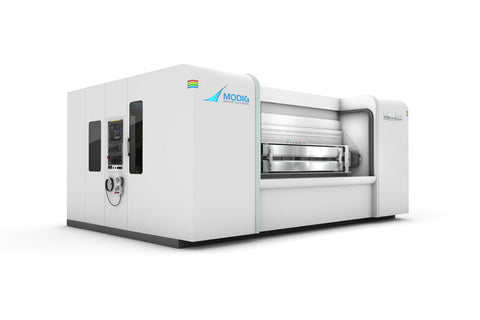

MODIG Mill-Ex multi spindle machine

NEW Mill-Ex high speed milling machine offers the lowest price per spindle for aluminium components.

Mill-Ex is a high-speed milling machine with single or multi-spindle individually driven in all three axes with up to 1.5G acceleration and high feed rates.

Mill-ex has the smallest footprint on the market for multi-spindle machines whilst providing high part throughput.

HOW THE MILL-EX ACHIEVES LOW COST PER PART MACHINING:

With an integral two position component carousel, whilst one part is being machined the next raw material section can be top- loaded into the carousel with the provision of a safety Bullet proof shield, thus saving down time.

Typical parts include extrusions for automotive (cross members) and aerospace such as floor beams, wing ribs and airframe among many other applications.

New raw material can be loaded in a pre-cut length DURING machining which increases part throughput AND reduces the overall cost per part.

Specifications:

- 4-axis horizontal machining centre with small footprint

- Single- or multi-spindle

- Extrusion machining

- Max part size: Diameter 20” (520 mm), Length 100″ (2,500 mm)

- Aluminium or composite materials

- Built to fit requirements

Options: Number of spindles, Spindle power, process cooling, measuring devices, loading and unloading.

Automation: Overhead loading system, robotic loading/unloading.

REPRESENTATION UPDATE:

Due to an increase in worldwide activity MODIG have elected to appoint distributors, rather than agents in many European markets. On 1st January 2025 Geo Kingsbury Machine Tools Ltd (Kingsbury) were appointed as the exclusive distributor for Modig MT in both the UK and the Middle East.

Kingsbury is a well established provider of machine tool solutions across many industrial sectors. M-Tech UK Ltd supports this agreement and will work with Kingsbury over the coming months to ensure a seamless transition process.

For UK or EIRE enquiries relating to MODIG Machine Tool Sweden Horizontal machining centres please email Mike who will share with Kingsbury, contact: MikeB@M-TechUK.com